The Moncler Group is committed to reducing packaging materials, as well as to researching and adopting lower-impact alternatives compared to conventional solutions. In recent years, the Group has also launched several programmes to improve packaging design, with a particular focus on recyclability and reusability1. All packaging products for end clients and used in logistics processes are made with “preferred” materials.

For logistical and production packaging, as well as the one intended for the end-client, and for use in the offices, since 2021 the Group has introduced a Manual, developed with the technical support of experts and in line with international standards, which defines the guidelines for the selection of “preferred” materials to be used for the creation of packaging and display items used in stores and window displays, with the aim of guiding all functions at Moncler and Stone Island that are responsible for designing and selecting these items.

The guidelines are based on key principles, including:

- reducing the amount of materials used;

- simplifying the structure of products with a view to eco-design by favouring mono-material or easily disassembled articles to promote reuse and recyclability;

- reducing the use of virgin raw materials, especially if from fossil origin, by favouring materials from renewable sources or recycling;

- designing items that can be used for a long time, re-used and recycled;

- selecting materials that have a validated environmental performance supported by documentary evidence and measurements, and, where possible, certified;

- using only materials that comply with the Group’s Restricted Substances List (RSL).

These guidelines have been shared with all the heads of department involved in their implementation and application in the areas of creativity and design, purchasing, research and development, sustainability and communication, through specific training sessions.

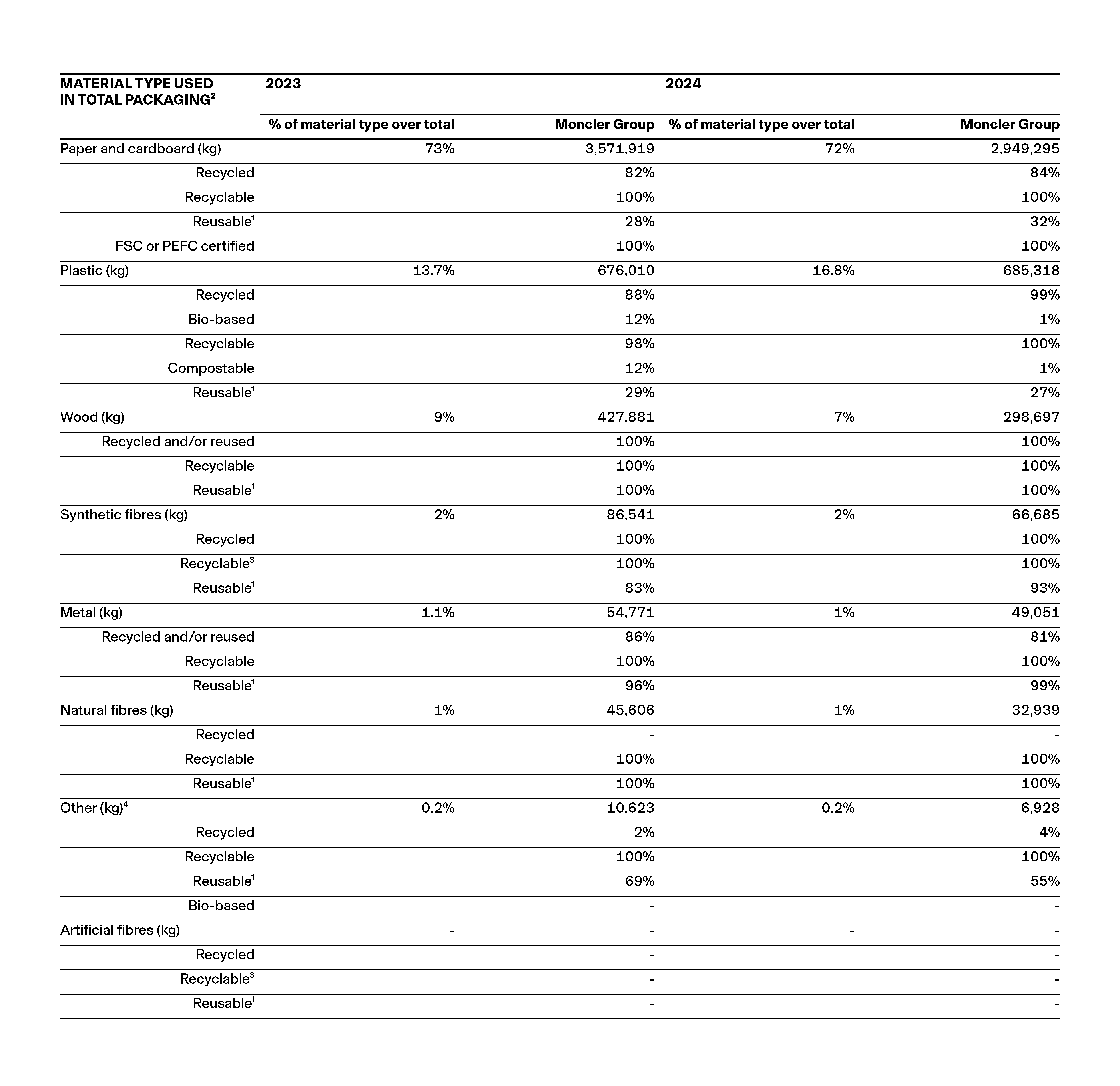

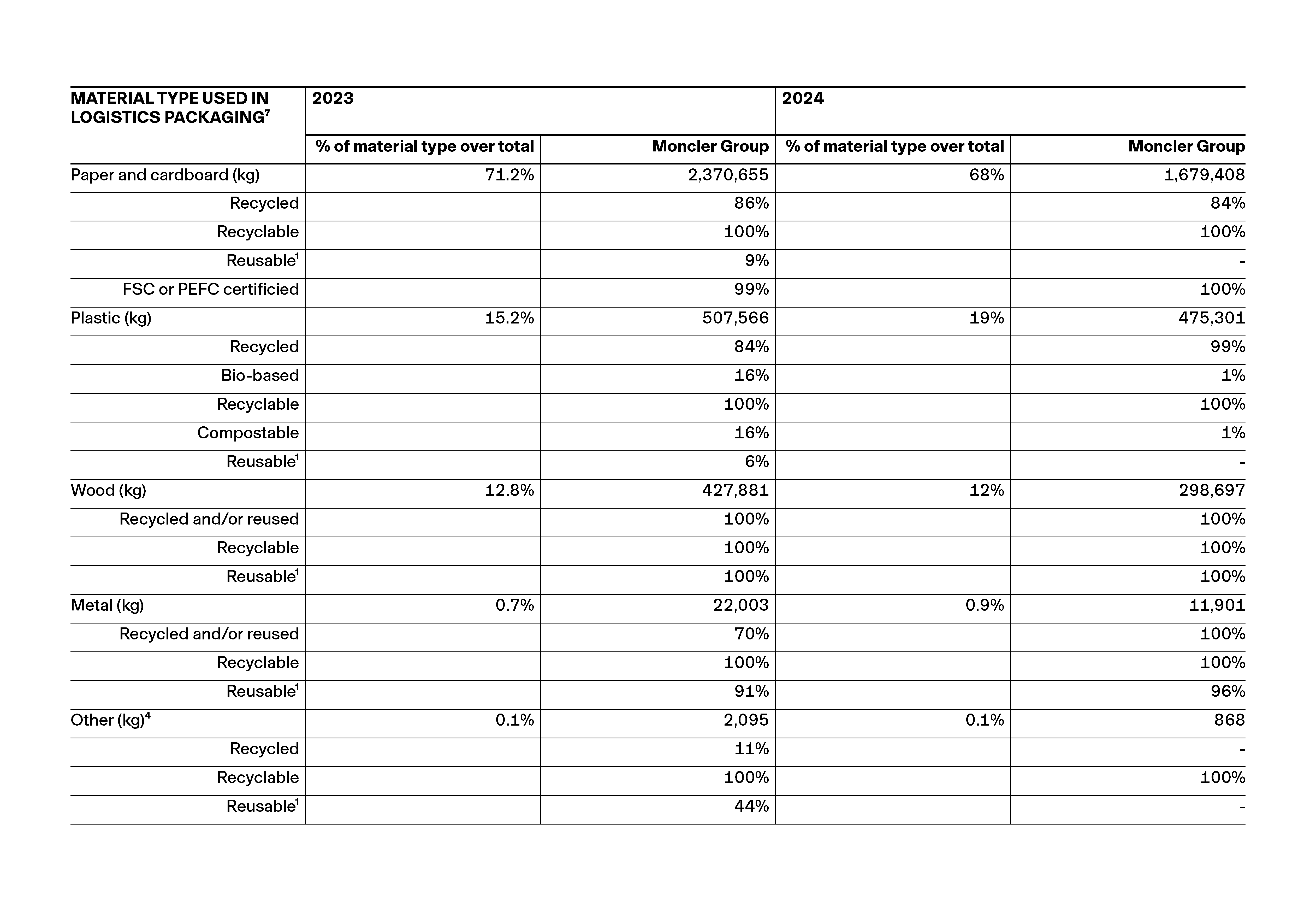

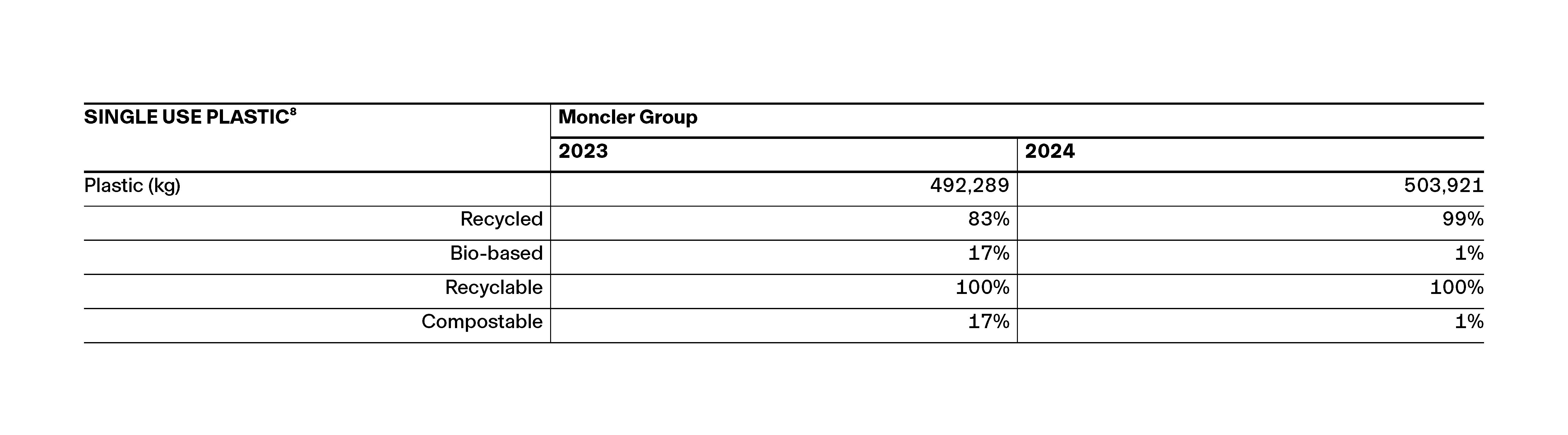

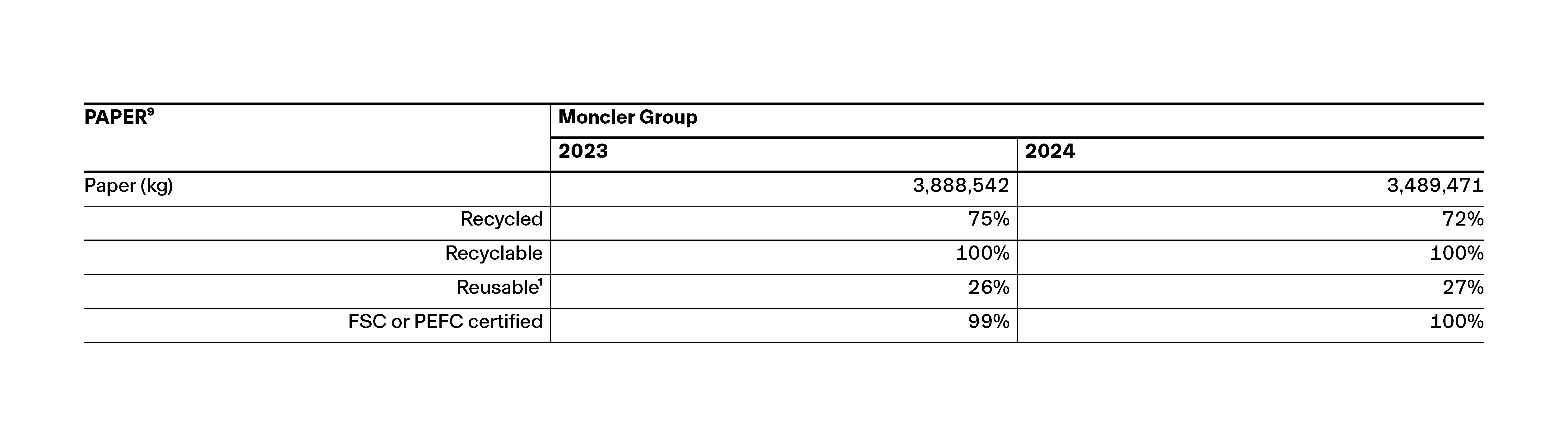

In order to promote recyclability, where possible, the use of a single material for the packaging of each item has been foreseen and at the Castel San Giovanni (Piacenza) logistics hub a recycling process was implemented, involving a private partner operating at the facility to ensure proper, effective management of the recycling of packaging materials. Moreover, Group’s offices and stores are equipped with special waste sorting containers and employees are informed of the importance of using proper practices so that waste can be recycled/recovered or, to a residual extent, disposed of. In 2024, 80% of the materials used for packaging (both logistical and intended for end clients) were both recyclable and recycled.

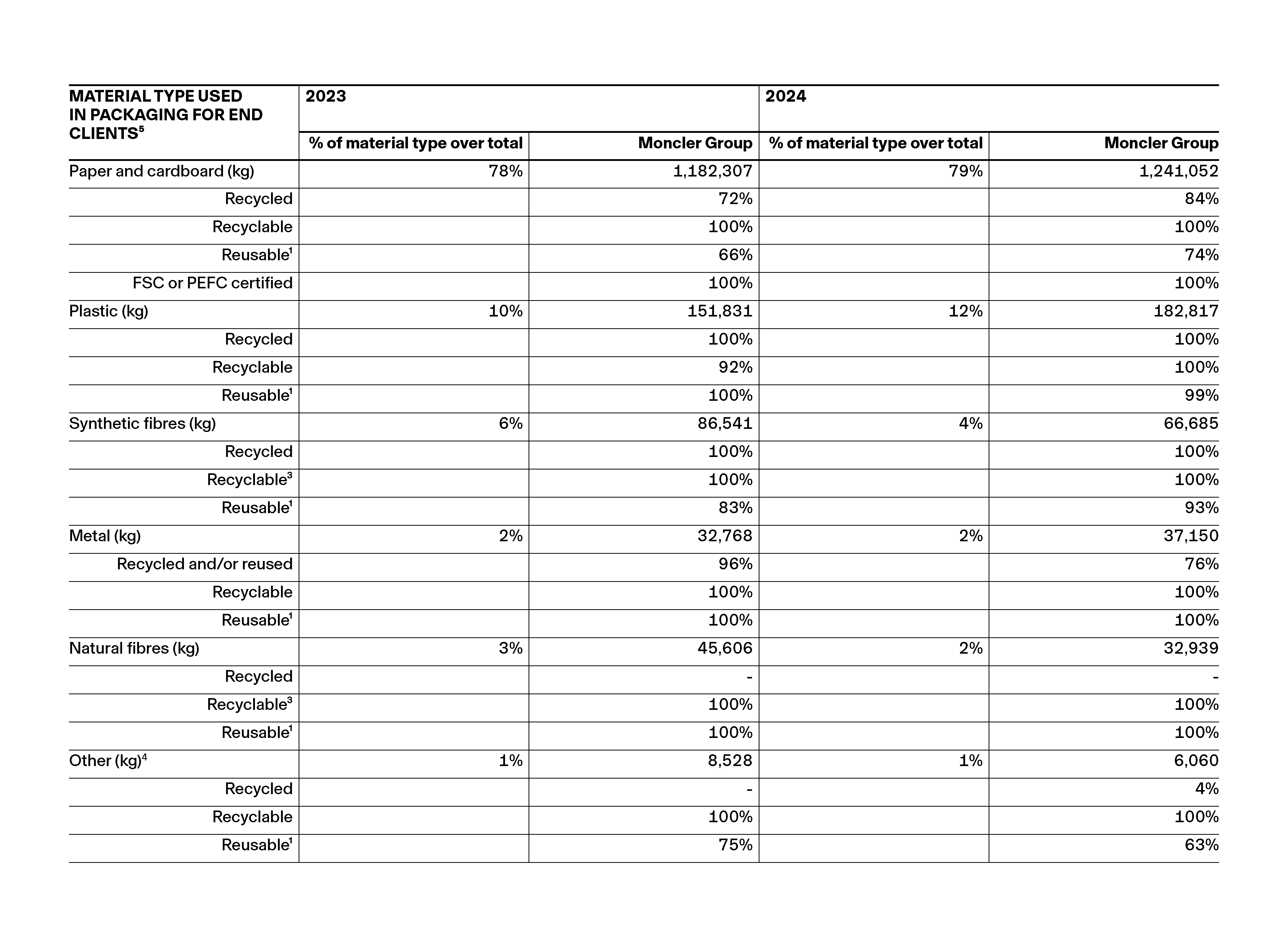

Regarding reusability1, 79% of the packaging intended for end clients was reusable, showing an increase compared with 2023 (72%).

The Group is committed, where feasible, to furtherly and continuously reduce year after year the volume of its packaging in order to improve the environmental performance of its products. Among initiatives to reduce weight and materials used, Stone Island, in 2021, replaced the traditional stone paper used for its shopping bags with recycled paper, resulting in a 35% reduction in the weight of each bag. Furthermore, over the years the Group has eliminated the single-use plastic packaging used for the logistic transport of shoes, and a procedure has been introduced to optimise the amount of packaging used for the internal shipment of samples of fabric and accessories between the various corporate functions, with consequent savings in the materials used. In addition, bands were eliminated from the Group’s logistics packaging in 2023.

For years, Moncler’s e-commerce channel has allowed clients to choose between two types of packaging made from “preferred” materials:

– “Signature” packaging: products are presented in a reusable Moncler box, tied with a tricolour ribbon. The external logistics box is made from 100% recycled paper from responsibly managed forests, while the inner box is composed of over 50% recycled sources. The inner garment covers, as well as the hangers, included with the down jackets, are made from post-consumer recycled plastic materials. In addition, last-mile delivery is done through the “UPS® carbon neutral” service for the Americas and EMEA Regions, whereas for Korea and Japan Moncler neutralises emissions through compensating projects;

– “Moncler Born To Protect” packaging (used for 80% of orders in 2024) that uses a reduced number of packaging layers, packaging products with lightweight and reusable materials. The external logistics box is always made from 100% recycled paper from responsibly managed forests, while the inner bags, as well as the hangers, are made of post-consumer recycled plastic. For this type of packaging as well, last-mile delivery takes place through the “UPS® carbon neutral” service for the Americas and EMEA Regions, with emissions compensating in Korea and Japan.

Despite the excellent results achieved, the Group is looking for continuous improvement. For this reason, annual R&D investments are allocated to explore and identify solutions with a lower environmental impact, also with the collaboration and assistance of international start-ups.