1 Approximately 90% of significant Group contracts include compliance with the Brands’ Code of Ethics (95% for Moncler).

Responsible sourcing

For the Moncler Group, talking about quality also means talking about health and safety, respect for human rights, environmental protection and, in general, ethics in business conduct along the entire value chain. Being a socially responsible company involves taking a commitment that extends well beyond its boundaries, embracing the entire supply chain.

SUPPLY CHAIN DUE DILIGENCE

To ensure proper and responsible management of workers throughout the value chain, the Group has adopted an integrated due diligence system in line with the OECD (Organisation for Economic Co-operation and Development) guidelines, which includes, in addition to the definition of standards and policies that suppliers must adhere to, risk analysis processes, mitigation actions, third party compliance verification by specialised entities and, when necessary, remediation plans, as well as the availability of whistleblowing and grievance platforms.

The due diligence process outlined covers all the human rights issues the Group identifies in its Human Rights Policy, and in particular among them: forced labor, human trafficking, child labor, freedom of association, right to collective bargaining, equal remuneration and discrimination.

THE GROUP’S POLICY SYSTEM

The Moncler Group has adopted specific policies in order to promote a responsible value chain in all the countries in which it operates, and to manage or mitigate theoretical risks and potential negative impacts.

The Codes of Ethics of the Moncler brand and the Stone Island brand encompass the set of values that both Brands recognise, share and also promote with all partners. Employees and collaborators are required to act with honesty and integrity and to build relationships with stakeholders based on mutual trust, so that growth is guided by the principle of shared value. In particular, through the Codes, the Group requires its partners to make the same commitment and, among other requirements, not to knowingly enter into relationships of any kind, either directly or indirectly, with parties who in any way violate the rules on adequate labour standards, with particular, but not exclusive, reference to the fight against child labour and forced labour as well as the protection of health and safety.

The Group’s Supplier Code of Conduct sets out expectations for how partners should operate. It consists of six sections (Labour and Human Rights – which includes a prohibition of any form of forced and child labour -, Health and Safety, the Environment, Animal Health and Welfare, Product and Service Safety and Quality, and Business Ethics) and contains the mandatory requirements that suppliers must comply with in order to begin or continue working with the Group.

The Group’s Human Rights Policy, which is an integral part of the Code of Ethics and is prepared with the technical support of the International Labour Organization (ILO), defines the principles underlying the Group’s commitment to respecting and promoting fundamental human rights and preventing or mitigating any negative impact of its activities through an approach based on risk assessment criteria at all levels of its value chain. All suppliers1, during the contractual phase, are required to sign the Code of Ethics, with its related Policies, and the Supplier Code of Conduct. By signing, suppliers commit to respecting its principles and ensuring that their own suppliers comply with them, as well as displaying these documents in the workplace to make them easily accessible to workers.

RISK ASSESSMENT

The risk analysis is carried out using various tools and applies to all entities within the value chain. It includes all the Moncler Group sites, existing and potential business relationships (e.g. mergers or acquisitions), potential and actual suppliers, sub—suppliers and their employees, including women, children, indigenous peoples and local communities, in any way connected to or affected by, directly or indirectly, the Group’s activities.

In particular, every year, the Group, with the technical support of a specialised international partner, conducts a specific risk assessment of environmental impact and human rights violations. The analysis, carried out at country level, covers all stages of the production process. As a result of this project, the potential risk profile by geographical area for each of the main human rights was mapped, including decent wages, health and safety at work, discrimination in the workplace, child labour, forced labour, inadequate working hours, human trafficking, migrant workers, freedom of association and collective bargaining.

The theoretical risk assessment analysis confirmed that the services and production processes carried out by the Group at directly managed sites do not present a significant risk profile for any potential human rights violations, while those managed by the Group’s direct suppliers and their supply chains are characterised by diversified levels of risk. In particular, the stages of the chain relating to cotton cultivation and the intermediate processing of the finished product might potentially be characterised by higher risk profiles than the other stages. For this reason, for years the Group has implemented structured monitoring and prevention processes aimed at mitigating these risks throughout the entire supply chain. Among the human rights analysed within the supply chain, ensuring decent wages has emerged as one potentially at risk. Indeed, for years the Group has been committed to monitoring this issue through specific analyses on the living wage. Lastly, the country-level analysis revealed the presence of higher potential risks in Southeast Asian countries, where the Group’s supply chain has a very limited presence. The Operations & Supply Chain and Purchasing & Procurement teams are periodically involved in training activities where the results of human rights risk assessment along the supply chain are shared.

PREVENTION AND MITIGATION OF IMPACTS

The risk analysis process is essential to prevent negative impacts and define mitigation actions, such as prioritizing ethical-social and environmental audit plans and integrating the results into the selection process for new suppliers.

The ethical, social and environmental audits are in fact carried out both on potential suppliers, to assess their suitability for establishing a business relationship with the Group, and on existing suppliers to verify ongoing compliance with applicable laws and the principles outlined in the corporate Codes. For the latter, any violation of the Group’s requirements constitutes a contractual breach, granting Moncler and Stone Island the right to request the immediate termination of the existing contract in the event of serious non-compliance or, in less severe cases, the implementation of a timely corrective action plan. In order to ensure maximum impartiality, audits are

regularly entrusted to independent, qualified, accredited third-party entities with recognized expertise. The audits, regarding social aspects, focus on verifying respect for fundamental human and labour rights, with particular attention to the issues of forced labour, child labour, freedom of association, working hours, guaranteed minimum wage, and, not least, health and safety. The Group’s proprietary checklist, used to perform audits, is regularly updated to take account of changes in reference standards and local and international regulations.

The checklist, prepared based on a benchmark analysis of the main standards and methodologies of recognized industry and multi-stakeholder initiatives such as SMETA, Responsible Business Alliance, amfori BSCI, and others, has been tailored to the peculiarities of the Group by integrating additional specific requirements. Subsequently, it was enhanced with technical inputs provided by the ILO. Since the Group included an human rights and environmental compliance modules in the DIST protocol, the checklist has been reviewed and approved by the DIST multi-stakeholder forum, which consists of Moncler people, representatives from certification and consulting companies (SGS, Control Union, IDFL, and KPMG), experts in auditing activities, in addition to representatives of international organizations such as the ILO, and other experts from the Department of Veterinary Medicine of the University of Milan, the Polish National Institute of Animal Husbandry, and Compassion in World Farming.

The Group has a three-year audit plan aimed at ensuring that all façon manufacturers and finished product suppliers are audited at least once every three years. In 2022-2024, Moncler conducted 794 ethical, social and environmental audits (on both suppliers and sub-suppliers), accounting for 100% of the volumes assigned to outerwear façon manufacturers, 93% of the volumes assigned to suppliers of other outerwear processes (dye houses, printing works, embroideries, etc.), 100% of footwear and bag suppliers, 88% of tanneries, 97% of volumes assigned to knitwear suppliers and soft accessories suppliers and 96% of the 2024 turnover of pattern making and prototyping suppliers. Stone Island, which has a three-year ethical, social and environmental audit plan to ensure the highest coverage of suppliers in its supply chain, also carried out 380 ethical, social and environmental audits during the same three-year period (on both suppliers and sub-suppliers), equal to around 100% of the value of orders assigned to finished products suppliers and 99% of the value of orders assigned to façon manufacturers.Moreover, in 2024, both Brands also conducted ethical, social and environmental audits on their main raw materials suppliers representing 75% of total material purchases for Moncler and 90% for Stone Island. In particular, with regard to the down supply chain, 100% of Moncler’s suppliers were also found to comply with the new human rights and environmental compliance modules officially included in the DIST Protocol. Those environmental and social modules were also applied to Stone Island’s RDS-certified down supplier verification processes. Lastly, ethical, social and environmental audits also continued to be carried out on strategic service suppliers: logistic platforms, external quality control platforms, providers of services at Group sites and stores for which no material non-compliance was identified.

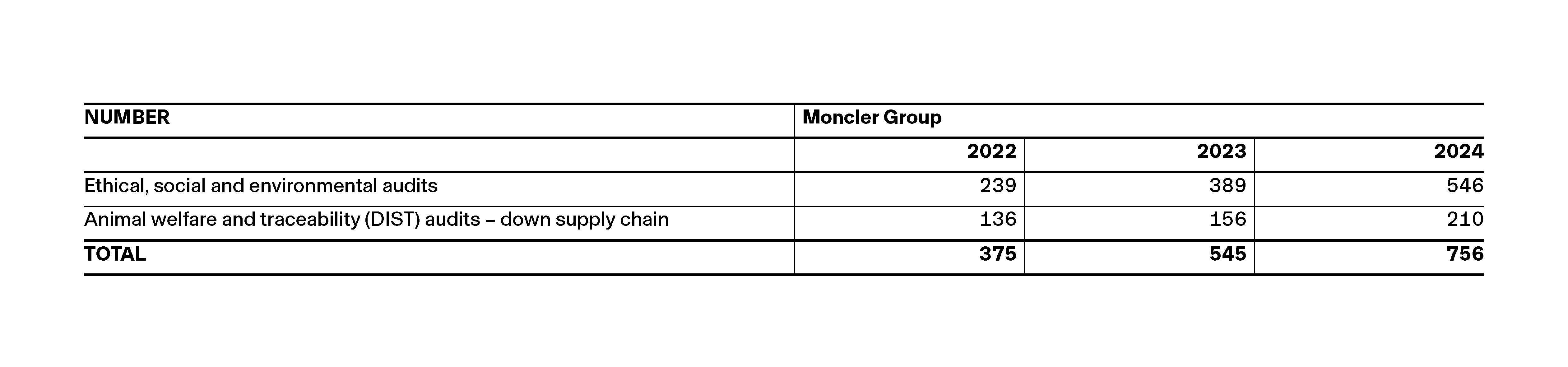

These verification activities were accompanied by audits on animal welfare and down traceability.

The increase in the number of ethical, social and environmental audits in recent years is also attributable to the strengthening of verification activities.

In 2024, with the ongoing goal of preventing impacts on suppliers’ workers and, at the same time, the potential risks for Moncler and Stone Island, the Group’s procedure applied to the selection process for new suppliers was updated. The evaluation of a new supplier involves an on-site visit conducted by the quality team to assess the supplier’s alignment with the Group’s quality standards and report potential visual critical social and environmental situations. After this technical analysis, the evaluation process for new façon manufacturers and new finished products suppliers involves a document review of compliance and financial aspects as well as a preliminary ethical, social and environmental audit carried out by a third party. For raw material suppliers, instead, the process requires the filling in of an environmental and social assessment questionnaire supported by documentary evidence followed by an on-site audit.

The Group thus commits to not include in its supply chain companies that do not comply with the Group’s quality standards and basic ethical, social and environmental principles.

The results of the audit activities, including preliminary ones, are regularly shared by the Sustainability and Internal Audit Functions with the Operations & Supply Chain and Purchasing & Procurement teams. This ongoing dialogue allows the latter to review the management of relationships with suppliers, also considering the potential risks and impacts on workers within the supply chain.

With reference to wage practices, which is another key topic in the fashion industry, in the Supplier Code of Conduct and in the Human Rights Policy the Group recognises the importance of ensuring wages that are aligned with the law or with binding collective agreements in force in the countries where it operates and, in any case, are adequate to the cost of living, the employee’s basic needs, discretionary profit, market benchmarks and the type of professional performance. The Group indeed requires its suppliers to offer the workforce a fair wage level and a career development path that reflects knowledge, skills, abilities, professional experience, as well as benefits and salary and non-salary incentives.

Suppliers, like the Group, are expected to both provide all the benefits required by the law, including but not limited to social security, parental leave, annual holidays and calendar holidays, and engage in regular social dialogue on compensation-related matters. In addition, all suppliers are required to full cover taxes and other recruitment and hiring costs for workers, including migrant workers, temporary workers and fixed-term contracts.

Since 2021, the Group, with the support of a third party, has been conducting specific assessments on living wage for both its own corporate sites and its suppliers, with the aim of covering 100% of its “critical suppliers” by 2025.

ADOPTION OF CORRECTIVE OR REMEDIAL MEASURES

If audit activities reveal violations of applicable laws or principles set out in the Group’s Codes and Policies, the Company requires the supplier to implement appropriate actions to resolve the non-compliance.

Notwithstanding the zero-tolerance approach for major breaches, for which the Group reserves the right to terminate immediately the existing contractual relationship with the supplier, both Brands are committed to support their supply chain raising awareness and driving continuous improvement, requiring the implementation of corrective actions where needed. Following each audit, an improvement plan is issued and its implementation is then verified. The Group undertakes to proactively support all suppliers in implementing the agreed corrective actions.

In order to verify that corrective measures are effectively implemented by the agreed deadline, the Group carries out both on-site and documentary follow-up audits.

With regard to the 546 suppliers sites audited on ethical, social, and environmental aspects in 2024, by the end of the year approximately 94% of them were in line with the highest Group’s social and environmental standards (more than 95% when considering “critical suppliers”). Relationship was terminated with around 3% of them (16 suppliers), and the remaining 3% turned out to have open non-compliances at the end of 2024, as the audit activity took place just before the last months of the year and not all the actions aimed at remediating the non-compliances had been closed.

With particular reference to social aspects, in 2024, 104 of the 546 audited sites were found to have non-compliances and the relative improvement plan was issued. The main areas of non-compliance were related to occupational health and safety (73%) followed by labour relationship management issues (23%), which included non-compliance regarding salary and wage treatment (11%), working hours (6%) and employment contract management (6%). Only 4% of the cases involved human rights-related issues. For least critical non-compliances, it was agreed with the suppliers to promptly implement a resolution plan, while in the most critical cases, the collaboration with the supplier was always terminated.

Finally, the Group examines each situation to assess whether any non-compliance identified has resulted in negative impacts on workers; in the event of proven negative impacts, the Group verifies whether or not these fall within the scope of its responsibility assessing their correlation with the performance of its activities. If such a correlation exists, the Group takes appropriate measures to remedy the impacts on workers in the value chain, collaborating, where necessary, with the competent authorities at national and international level and with its suppliers and partners to adequately address these situations. The Group also expects its suppliers and business partners to adopt mitigation and remediation measures for human rights violations in their activities, integrating these obligations into their contracts.

The due diligence process has contributed to strengthening over time the awareness and culture of human rights, as well as the risks associated with them, both within the Company and along the supply chain. The actions taken have proven their effectiveness over time, leading to the selection of suppliers with progressively lower risk and demonstrating that non-compliances, resolved thanks to the improvement plans implemented during the

three-year audit cycles, do not recur in subsequent audits.

The due diligence activities, carried out using the various tools and methodologies described in the sustainability report, covered the Group’s entire value chain — including both the supply chain and the activities of Group companies and joint ventures. The specific assessments conducted in 2024 to identify potential human rights risks did not reveal, as of year-end, any cases classified as high risk for human rights violations.

All the activities described so far, both those of periodic monitoring and control of the supply chain and those of collaboration and dialogue with suppliers to promote more sustainable and responsible practices, are part of the Moncler Group’s program defined for suppliers on sustainability topics.

In this context, the Group has defined a governance system aimed at guaranteeing harmonization between the sustainability strategy for the supply chain and the Group’s purchasing practices. Above all, a Control, Risk and Sustainability Committee has been established at Board level which is entrusted by the Board of Directors with supervising the implementation of all sustainability practices, including responsible sourcing with all related activities included into Group’s program defined for suppliers on sustainability topics. This committee acts with the support of various corporate functions (including the Sustainability Unit and the Operation Team) that have operational responsibility for carrying out the various activities, for each area of responsibility, within the program.

Moreover, the Group pays special attention to the management of its purchasing practices in order to ensure their alignment with the Group’s Code of Ethics and Supplier Code of Conduct and to avoid potential conflicts with sustainability requirements. To this end, it has also adopted a Purchasing Policy, which defines roles, responsibilities and fundamental principles for the management of purchases, ensuring transparency, fairness and regulatory compliance, and applies to all Group Companies. The purchasing practices are periodically reviewed and updated, and all Group’s employees involved in their implementation (both buyers and other employees who are in contact with suppliers) are trained on their proper application and on the principles of sustainability and responsibility most relevant to their work (in particular, for example, a specific training course on the principles of the Code of Ethics and a training course on Human Rights are provided).

As evidence of this, the guidelines to be followed for the purchase of all packaging used by the Group have recently been further updated precisely in order to keep them in tune with the latest scientific developments in the area of materials with a lower environmental impact; in addition, the Responsible supply chain team is responsible for periodically updating the Raw Material Manual, which summarizes the criteria and thresholds that guide the choice of “preferred” materials with lower environmental impact compared to conventional solutions and which are integrated into the purchasing practices of all raw materials purchased by the Group.

FAIR WAGE PRACTICES ALONG THE VALUE CHAIN

Moncler partners with the Fair Wage Network, an independent organisation dedicated to progressing fair wage practices across global supply chains. The methodology adopted by the Fair Wage Network involves collaboration with companies and suppliers to assess wage practices through questionnaires completed by both workers and managers, identifying any problems and suggesting improvement actions.

The Fair Wage Network assessment methodology is structured around 12 dimensions, covering the entire spectrum of wage indicators: the living wage is therefore only one of the dimensions analysed, alongside other aspects and variables of the wages practices and pay systems are evaluated such as wage negotiation with workers’ representatives through collective bargaining, the presence of grievance mechanisms for complaints on remuneration issues, etc.. Another area of the analysis involves comparing the results of the assessment with industry and country-specific benchmarks.

The implementation of this analysis and the gradual extension to other Group suppliers have been assessed and prioritised on the basis of the risk profile associated with the geographical location of the supplier and other factors, such as the presence of collective labour agreements, which ensure dialogue and respect for social and environmental aspects. In this regard, approximately 70% of the Moncler Group’s suppliers are located in Italy and are covered by collective bargaining agreements. At the end of 2024, the percentage of “critical suppliers” assessed and involved in a living wage analysis, carried out with the Fair Wage Network, was equal to 86%. The analysis, which in the last three years has involved more than 16,000 workers of the Group’s suppliers, confirmed that all of these workers receive remuneration in line with or above the applicable local minimum wage according to current regulations. In particular, the results show that more than 85% of the workers involved in the assessment receive a salary in line with the country-specific living wage (where possible, region-specific) and parameterized according to specific indicators for that country, such as the average fertility rate and the average number of people per household who receive an income from work.

In general, the Group is committed to work with all players in its supply chain, specialised associations and other strategic partners to increase awareness and understanding of the issue of fair wages.