1 Endorsed by CDP, the United Nations Global Compact, the World Resources Institute (WRI) and the World Wide Fund for Nature (WWF), the Science Based Targets initiative establishes and promotes best practices in setting science-based targets, in addition to evaluating companies’ targets.

2With reference to the targets set, there are no locked-in greenhouse gas (GHG) emissions associated with the Group’s owned assets. As a result, there are no identified risks that these emissions could hinder the achievement of GHG emission reduction targets. Despite this, the Group continues to constantly monitor its assets to ensure the necessary flexibility to adapt to sustainability and emission reduction targets.

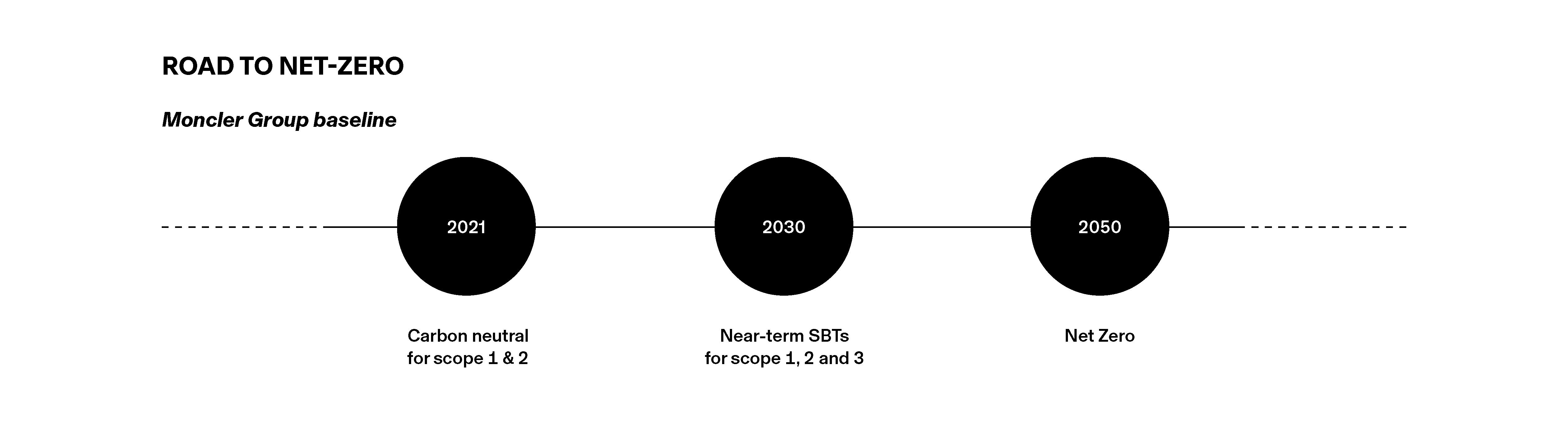

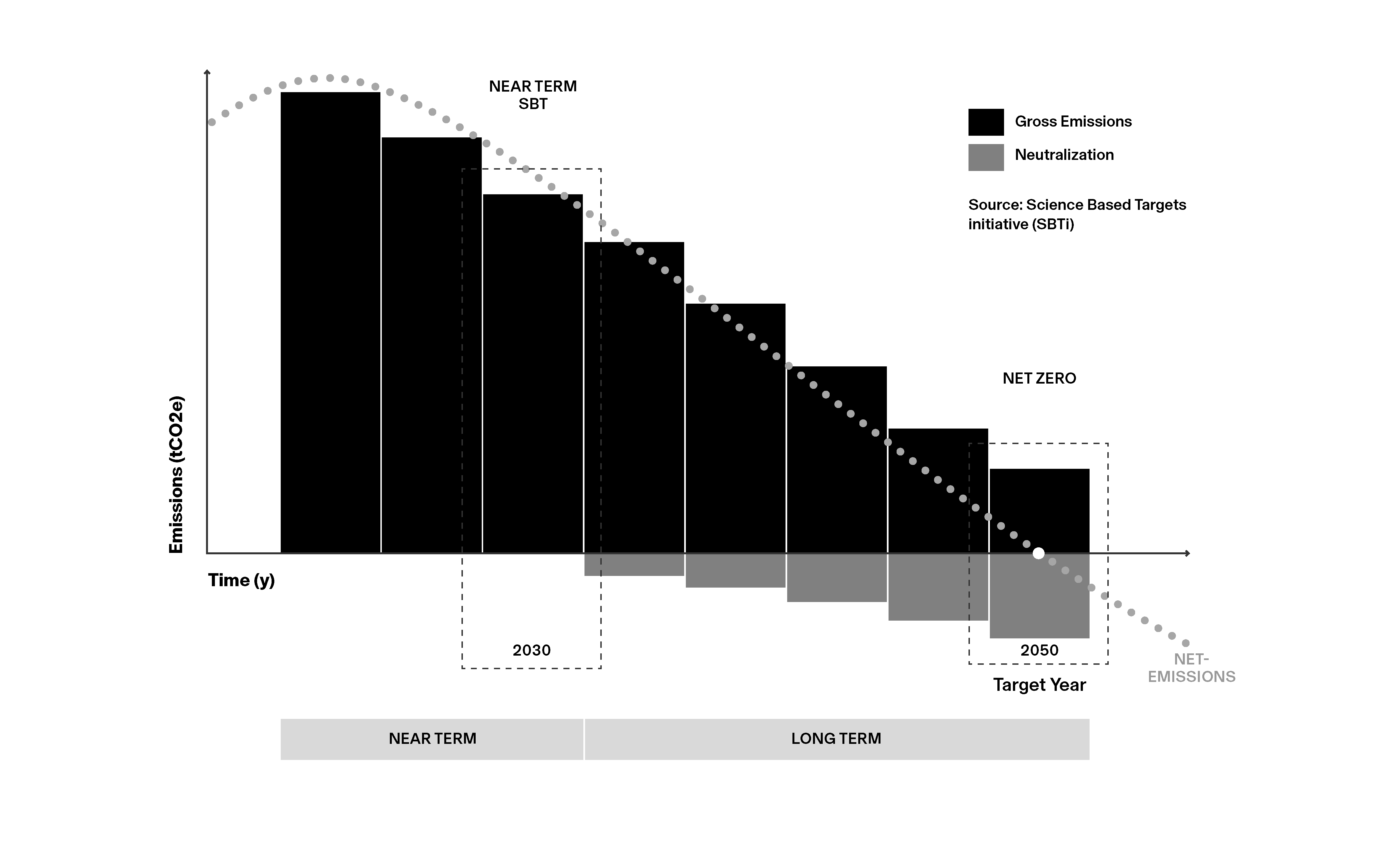

3 According to the United Nations Intergovernmental Panel on Climate Change (IPCC), net zero emissions are achieved when the complex balance between greenhouse gas (GHG) emissions produced and those absorbed by the ecosystems is achieved through offsetting mechanisms. In particular, to contribute to the achievement of net zero emissions, companies have to reduce emissions and offset residual emissions. According to the Science Based Targets initiative, the achievement of Net Zero involves scope 1, 2 and 3 GHG emissions.

4 For the calculation of electricity and gas consumption, data were collected for the first ten months of the year, where available, while for the remaining months or in the case of partial information, consumption was estimated.

5 The data include the consumption and emissions of the car fleet with reference to the global perimeter for 2024 and 2023. In 2024, the Group’s car fleet included more than 90% hybrid and electric vehicles, to which the respective vehicle consumption factors have been applied.

6 The data include the total energy consumption calculated on the basis of the information collected through the utility bills.

7 This includes electricity consumption related to full-electric vehicles in the fleet in line with the GHG Protocol guidelines.

8 This figure includes green energy certified through Energy Attribute Certificate (EAC), including the Renewable Energy Certificate (REC)/Guarantee of Origin (GO)/International Renewable Energy Certificate (I-REC)/Non-Fossil Certificates (NFC).

9 This figure includes the consumption of electricity from the photovoltaic systems installed on the Group’s sites.

10 In 2024, energy generation was lower than in 2023 due to a failure at one of the Group’s photovoltaic plants, which temporarily compromised its operation.

11 The Group’s companies operate in the sales and retail sector (NACE Section G), classified as high climate impact. All revenues generated and energy consumption are attributed to these activities. Revenues correspond to what is reported in item 4.1 Revenues in the Explanatory Notes to the Consolidated Financial Statements.

12 High climate impact sectors are those listed in NACE Sections A to H and Section L (as defined in Regulation (EU) 2019/2088 and Annex 1 of the relevant Delegated Regulation regarding disclosure rules on sustainable investments).

13 For the calculation of emissions, financial control was considered, which coincides with operational control, for all scope 1 and scope 2 emissions.

14 The increase in emissions compared with 2023 is mainly linked to the introduction of petrol hybrid company cars to replace vehicles powered exclusively by diesel, resulting in an increase in the petrol consumed in 2024.

15 No refrigerant gas leakages were recorded in 2023.

16 The Group, at the moment, operates outside the Emissions Trading System (ETS) regulated emissions market, as it does not fall within the sectors or activities subject to the monitoring and trading obligations of the European ETS.

17 The latest-generation LEDs, in addition to offering excellent light quality, ensure an estimated energy savings of up to 80% compared with previously used lighting systems, while also generating less residual heat. In terms of environmental impact, LED lights have an average lifespan that is significantly longer than traditional lights and are almost entirely made from recyclable material.

18 Excluding the shop-in-shops, where lighting systems are provided by the host department stores (17 worldwide) and on which, therefore, Moncler cannot take action. However, by the end of 2024, such shop-in-shops were equipped with LED lighting systems.

19 Excluding shops-in-shops.

20 This value represents the average price of carbon allowances in the EU Emissions Trading System (EU ETS) auctions for the first half of 2024, the primary carbon market in Europe. (EC report on the functioning of the European carbon market, 2024).

21 Achieving carbon neutrality involves reducing impacts through CO2 emission reduction activities such as purchasing energy from renewable sources, using more efficient lighting systems, using vehicles with low environmental impact and compensating residual emissions with carbon credits generated by positive impact projects. Each credit, certified according to international standards, such as the Gold Standard or Verified Carbon Standard (VCS), certifies that a tonne of CO2 has been reduced or removed from the atmosphere.

22 The average percentage annual reduction of Scope 3 emissions against the 2030 reduction target compared with the 2021 base year is approximately 1.5%.

23 The value is calculated considering the emissions that would have been generated if the Group had used conventional raw materials.

24 Distribution logistics is responsible for the management of transport and distribution of finished products to clients. Industrial logistics handles the management of material flows upstream in the supply chain.

25 Well-to-Wheels (WtW) value. Emissions from logistics transport have been calculated in accordance with the GLEC Framework 3.0.

26 The figure is calculated by applying location-based emission factors to all scope 3 categories, except for the category “Third-party warehouses” and “Purchased goods and services”. The emissions associated with these categories, for which primary data is available, have been included in the calculation by applying the relevant market-based emission factors.

27 The percentage of scope 3 emissions calculated from primary data in 2024 is approximately 70%.

28 CO2e emissions were calculated using regionalised emission factors for both the cultivation and farming phase of raw materials and for the production processes along the supply chain of the most important material codes for the Group. This was made possible thanks to the information collected for the purposes of the Group’s traceability goals.

29 Primary data on energy consumption from certain suppliers were used, gathered both through onsite energy assessments and through a campaign to collect specific information on the energy practices adopted at the production sites of direct and indirect suppliers.

30 For the calculation in 2024 of Capital goods category, a more accurate methodology was used, as more granular data was available. This methodological refinement applied to previous years would result in a non-material variation.

31 This category is not applicable to the Moncler Group, as the Group does not use leased assets from third parties,whose impacts are not already included in the scope 1 and 2 reporting.

32 This category is not applicable to the Moncler Group since the sold products do not require further processing or transformation.

33 This category is not applicable to the Moncler Group as it does not own assets leased to other companies.

34 This category is not applicable to the Moncler Group business model, as the Group does not own franchises.

35 This category is not applicable to the Moncler Group since all the companies in which the Group invests are fully consolidated, therefore emissions are already included in scope 1 and 2 data.

36 This refers to the ability of a product to be used multiple times or in multiple contexts without losing its functionality, performance or quality.

37 A non-profit organisation that recognises and rewards farmers for their environmental practices.

38 Official certification body for the Gold Standard for the Global Goals, the most credible and robust standard aimed at ensuring that climate actions also contribute to the Sustainable Development Goals.

39 An organisation active in insetting practices since 2008, PUR Projet is a certified B Corp and a global leader in the implementation of nature-based solutions.